What kind of heat transfers printing?

Introduction to heat transfer printing: types, advantages and disadvantages

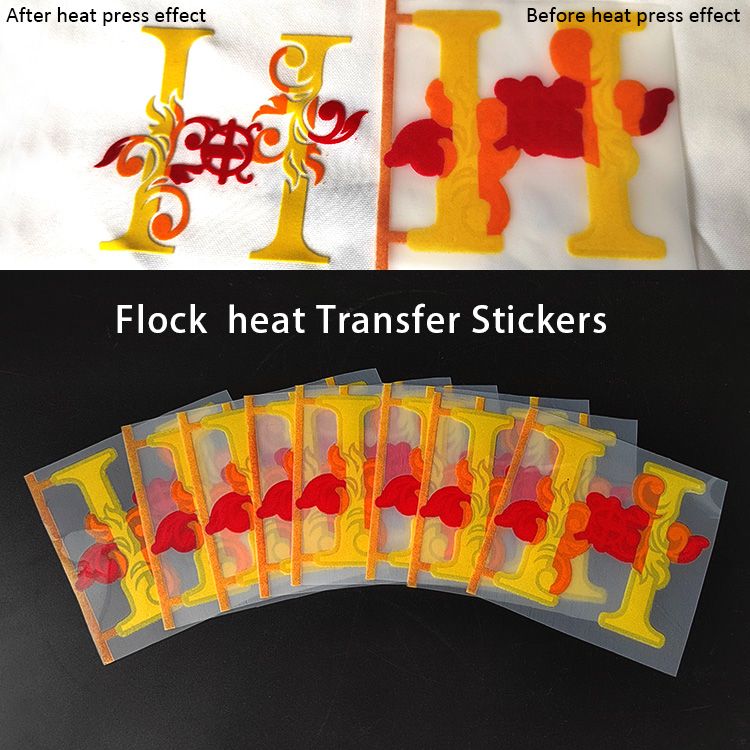

Heat press transfer is a commonly used decorative technique that achieves decorative and personalized effects by transferring patterns or images from special paper to textiles or other materials. This technology has been widely used in clothing, home decoration, gifts, and other industries. This article will introduce in detail the types of heat transfer printing and their advantages and disadvantages.

Types of heat transfer

1. Printing and heat transfer

Printing heat transfer is one of the most common types of heat transfer. It uses special color pastes or dyes to print patterns directly onto textiles. This method works with patterns of all colors, complexity, and sizes. Printing heat transfer can achieve high resolution and a rich variety of patterns, while still maintaining the softness and breathability of textiles.

2. Foil heat transfer

Foil heat transfer is a method of transferring patterns to textiles through heat transfer film. Thermal transfer films are usually made of polyvinyl chloride (PVC) or polyester (PET) and are available in a variety of colors and effects. Foil heat transfer can achieve high durability and good hiding properties, and is suitable for a variety of textiles.

3. Kangaroo heat transfer

Kangaroo heat transfer is a heat transfer method that transfers a pattern to a backing film. The backing film is usually made of polyvinyl chloride (PVC), which is soft, elastic and durable. Kangaroo heat transfer is suitable for patterns in a variety of colors and sizes and can be used on a variety of materials such as textiles, leather and plastics.

Advantages and Disadvantages of Heat Transfer Printing

advantage:

Personalized design: Heat transfer printing technology can realize personalized design and decoration needs, helping products to be unique.

Pattern Complexity: Whether it's a simple logo or a complex illustration, pyrography heat transfer accurately reproduces and keeps pattern details clear.

Durability: With proper treatment, heat transfer patterns can have high durability and withstand normal use and washing without fading or wear.

Suitable for a variety of materials: Heat transfer printing can be applied to a variety of materials, including textiles, leather, plastics, etc., providing more choices for different industries.

shortcoming:

Higher costs: Compared to other decoration techniques, heat transfer printing may involve higher production costs, especially when producing on a small scale.

Limited color selection: Some heat transfer technologies have limited color selection and cannot achieve overly complex or special color effects.

Processing requirements: Heat transfer requires temperature and time control

Next: How to do UV DTF stickers?

Previous: What kind of Puff heat transfer vinyl

Heat Transfer Vinyl

Heat Transfer Vinyl is widely used in clothes, leather products. The basic theory is that the vinyl has hot melt agent on surface and users can heat press the vinyl on fabrics or leathers when heat it. HTV vinyl has 3 to five layers, and they are base layer, release layer, printing layer, adhesive layer and hot melt powder.So it looks all the same on appearance, however there are different materials to make different quality vinyl.